Our Technologies

Non-Contact Magnetometry Inspection Technology

The innovative and field-tested Non-Contact Magnetometry (NCM) method from Hazaika Energy is the ideal solution for inspecting buried pipes. It was developed in response to the challenges faced by operators when inspecting such pipelines.

It works by identifying changes along a pipeline’s magnetic field, which are caused by stress, tension or corrosion. The received data is visualised in real time and shows the locations of anomalies along the pipe, complete with GPS coordinates.

Advantages of NCM

NCM inspections can identify anomalies that are caused by the following types of problems on pipelines:

- Metal Loss

- Crack-like Defects

- Pipeline Geometry Changes (loss of stability)

- Stress-strained Condition

- Mechanical Damage

- Weld Anomalies

NCM can easily be deployed onshore and can also be deployed subsea by a diver or mounted on an ROV. The device is lightweight and is rated for a water depth of 2000m.

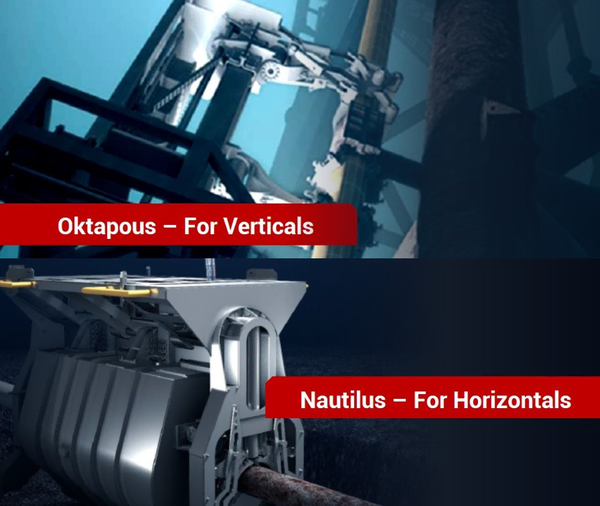

Subsea Pipeline Repair Robots

The Nautilus and Oktapous are subsea robots that are designed to perform inspection, repair and maintenance tasks on subsea pipelines and risers with minimal human intervention and a very light footprint.

These robots have the distinct advantage of being able to assess, clean and repair subsea pipes in a single operation without requiring divers and most of the conventional vessel-supported equipment.

Features

- Able to operate on a wide range of ‘live’ pipelines

- Removal of marine growth and pipe coatings and preparation of pipeline surface for repair

- Defect verification and sizing, right before the repair process is initiated

- Creation of a controlled atmosphere around the defect to ensure consistent results and high-quality repairs

- Autonomous repairs in line with standard procedures

- No harmful discharge to the environment

Transform Your Operations With Our Proven Expertise

Hazaika Energy Limited is a certified Integrated Energy Services provider, with a focus on technology solutions for Asset Integrity Management, Oilfield Management, Smart Manufacturing, and Sustainable Energy.

Navigation

© 2026 Hazaika Energy Limited. All rights reserved.